United Aircraft owns complete composite product solutions.

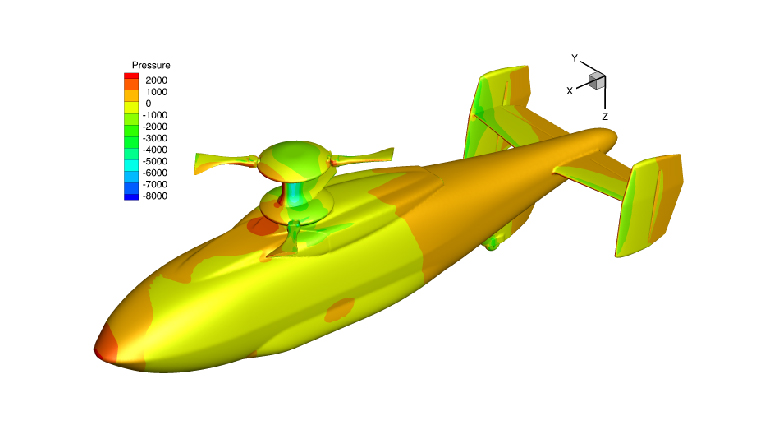

According to the user's requirements for functions and performance, United Aircraft has formulated design rules for comprehensive design from aspects of structural functions, dynamics performance, service environment, maintainability, weight reduction, manufacture cost, etc. Relying on the structural design platform established by the company and the simulation platform, design can be detailed. United Aircraft is capable of static load analysis, vibration mode analysis, stability analysis, non-linear calculation, impact analysis, and other simulation analysis and calculations as well as design in configurations, lay, connection, corrosion resistance, lightning protection, etc.In terms of composite product solution schemes, United Aircraft has accumulated a mass of experience, including applications on manned military aircraft, manned civil aircraft, unmanned helicopters, fixed-wing UAVs, missiles, and loitering munition.