United Aircraft has established a set of optimization and design process for rotor aerodynamic configuration with hovering efficiency and forward flight lift-drag ratio as its optimization objectives. In terms of airfoil selection, United Aircraft sorts out ZA series airfoils including thickness of 7%~12% on the basis of the existing open airfoil database, based on which, it optimizes the airfoil distribution. Furthermore, United Aircraft has also established a set of optimization process for the blade tip shape, which help effectively improve the rotor's aerodynamic characteristics and reduce the aerodynamic noise.

So far, taking the take-off weight, elevation, and flight speed requirements raised by different platforms into consideration, United Aircraft has finished the rotor aerodynamic design for TD220 and T333 platforms and the relevant test flight verification.

United Aircraft has carried out the following work according to the industrial specifications, standards, and relevant requirements for technical specifications: material selection for propeller hub and control design, confirmation of structural parameters, configuration selection, calculation of strength/rigidity/fatigue strength, design of parts and assemblies, motion simulation, interference check, and "Six Abilities" design. As a consequence, by leveraging the self-developed blades, an unmanned helicopter rotor system featuring high safety and reliability, convenient control, and peerless performance is brought forth. Currently, the Group can carry out R&D for propeller hubs of semi-hinged, bearingless, hingeless, and universal-hinged types and for auxiliary control.

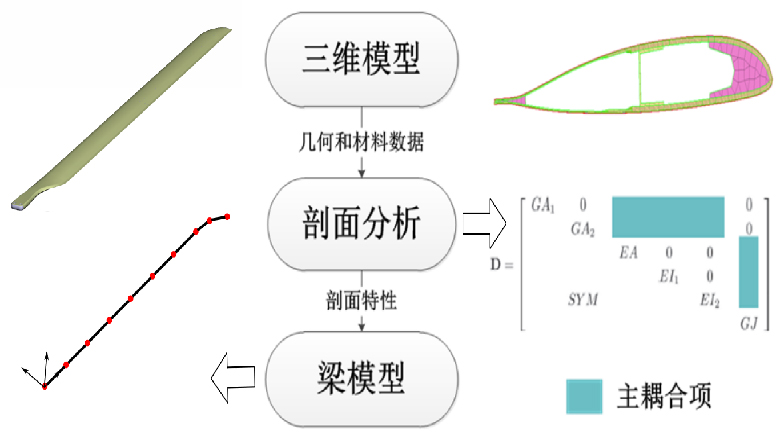

To better carry out the rotor dynamic design, United Aircraft designs a profile characteristic parametric calculation tool for batch analysis of the blade profile's structural characteristics; establishes and solves the rotor dynamic model by using the rotor dynamic comprehensive analysis software; develops the rotor optimization framework software, optimizes blade parameters, properly configures the rotor dynamic frequency, and improves the blade's service life. With all the above-mentioned measures, the service life of the composite blade can reach more than 6000 hours, greatly enhancing the safety performance of the rotor system and reducing the life-cycle cost of blades.

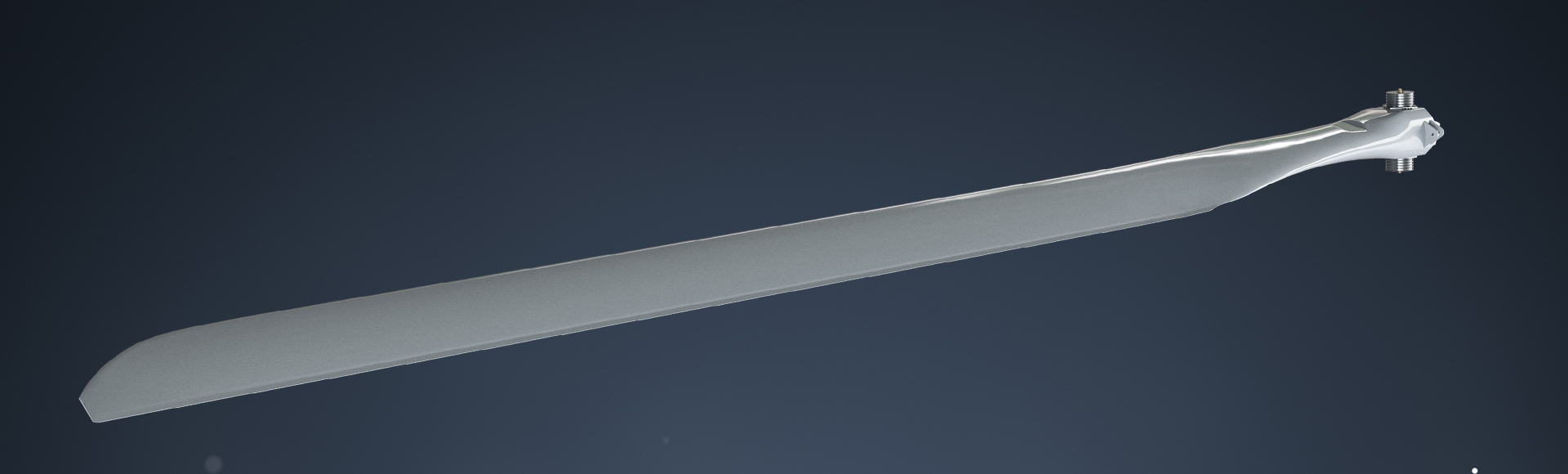

Up to now, United Aircraft has successfully designed and manufactured the semi-hinged rotor blade with the diameter of 4.6 m, hingeless rotor blade with the diameter of 6.4 m, and bearingless rotor blade with the diameter respectively of 6 m and 10.2 m.

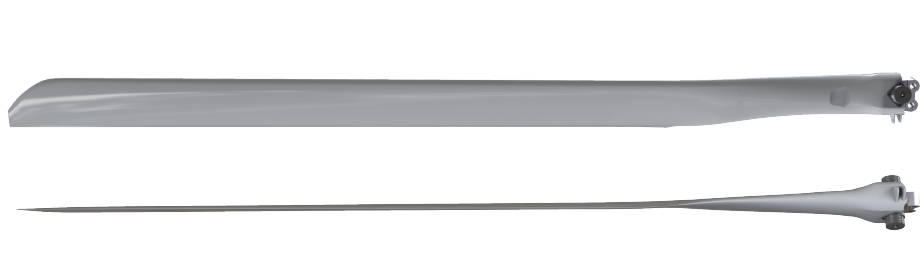

Blade manufacturing adopts the hot pressing, curing, and moulding process by using the enclosed mold to ensure that the blade profile can tightly fit with the mold cavity's profile so that the critical contour parameters such as the blade torsion angle, airfoil profile accuracy, and surface roughness can accurately satisfy the design requirements. United Aircraft is skillful in manufacturing, balancing, and inspecting the composite blades, and has mastered the technologies for manufacturing of the blade moulding mold, machining of the internal foam core of blade, moulding of chopped fiber fabricated parts, winding and form maintaining of girder strips, lamination and assembly of blades, co-curing moulding, boring, static balancing, and 3-coordinate testing.

United Aircraft has completed manufacturing and verification of the conventional blades with the rotor diameter respectively of 4.6 m and 6 m as well as the bearingless rotor blades with the rotor diameter respectively of 4.6 m, 6 m, and 10.2 m.

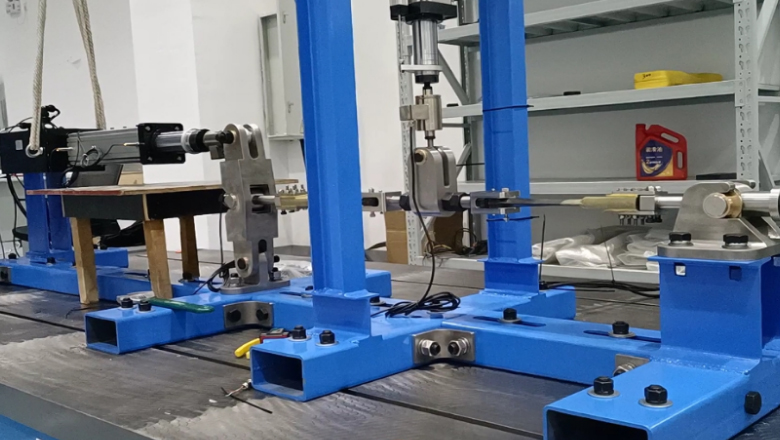

So far, United Aircraft has been competent in blade performance analysis and failure analysis and evaluation, mainly including test capabilities of static and dynamic characteristics, static strength and fatigue strength for blades, flight load for blades, and rotor cone and dynamic balance, etc.